The Benefits of Electric Forklifts

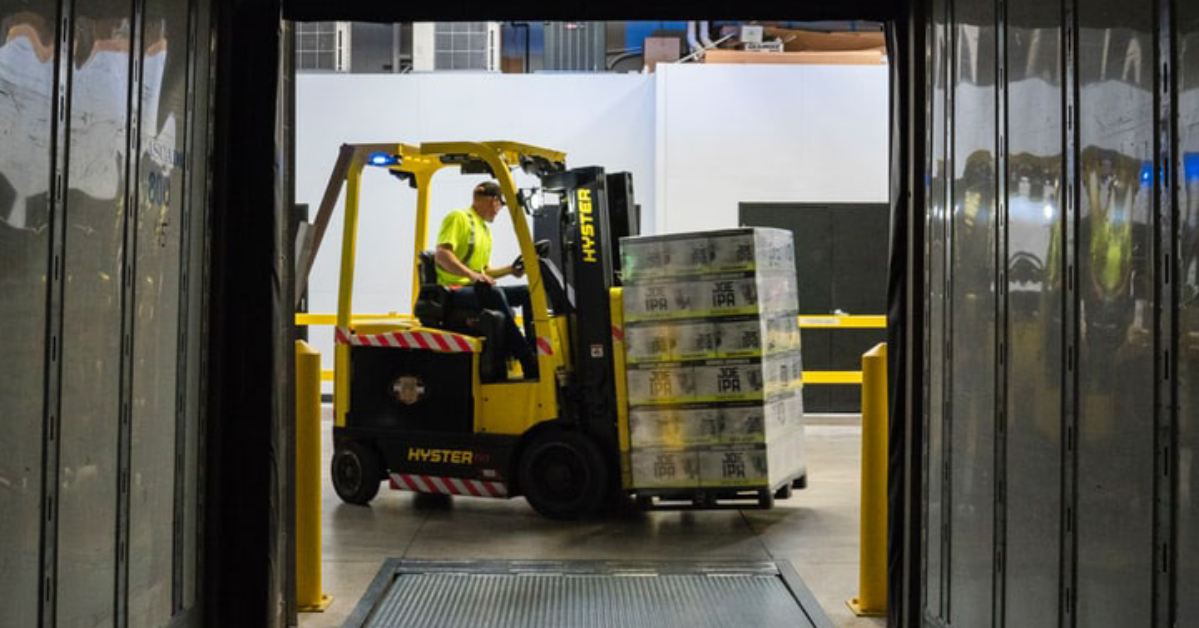

Not long ago, electric forklifts were only a minor segment of the total U.S. forklift market. Now, electric forklifts have become the forklift of choice at many job sites.

Gas-powered forklifts aren’t going away anytime soon, but electric forklifts have many advantages over their gas-powered counterparts. At the same time, diesel and propane forklifts still make up a big part of the U.S. forklift market. But, they are also giving way to the increasing demand for cheaper and more eco-friendly electric forklift types. Going forward, electric forklifts will likely soon outsell all fossil fuel forklifts.

Electric Forklift Benefits

Key reasons why businesses often choose electric forklifts over all other varieties include:

- No tailpipe emissions

- Quieter than other types of forklifts

- Do not require outside storage of tanks

- Minimal maintenance in comparison to other types of forklifts

- Lower total cost of ownership in comparison to other types of forklifts

- Low center of gravity

- Fewer waste fluids in comparison to other types of forklifts

Before you purchase an electric forklift, it is generally a good idea to conduct plenty of research. This ensures that you can learn about electric forklifts and how they perform in contrast to other types of forklifts. It also allows you to learn about the different types of electric forklifts.

Share this Image On Your Site:

Electric Forklift Types

Here are 10 of the most common types of electric forklifts:

- Warehouse Forklift: Mainly used for loading and unloading pallets and other materials.

- Side Loader: Used to move bulky, heavy loads at manufacturing job sites.

- Counterbalance Forklift: Has forks in the front and a counterweight in the back to help balance heavy loads; this type of electric forklift is ideal for jobs that require driving in circles.

- Telehandler: Features an articulating boom and arm attachment; a telehandler is frequently used to lift loads to high elevations.

- Industrial Forklift: Uses hydraulic levers for extra reach and power; an industrial forklift is mainly used to transport heavy loads in industrial settings.

- Rough Terrain Forklift: Features oversized tires and a reinforced cab; this type of electric forklift is designed for use at outdoor sites and can be used on uneven or rocky ground.

- Pallet Jack: Consists of a small forklift powered by hand or batteries; this electric forklift is designed to handle pallets in tight spaces.

- Walkie Stacker: Moves pallets to greater heights than a pallet jack.

- Order Picker: Offers a great option for piece-picking items off shelves by hand.

- Reach Fork Truck: Features stable legs for quick, precise picking of pallets at warehouses.

Learn about the different types of electric forklifts, and you can make an informed decision about whether an electric forklift is the right choice for your business.

Why Electric Forklifts Are More Efficient Than Gas-Powered Forklifts

Reasons why electric forklifts tend to be more efficient than gas-powered forklifts include:

- Performance: Electric lifts have superior braking technology and can turn on a smaller radius than gas-powered lifts. They also feature advanced tire technology, which makes electric lifts easy to control.

- Cost:A standard gas forklift costs three to five times more to operate than an electric lift. Electric lifts also require fewer tune-ups than gas-powered lifts. Plus, they usually have fewer engine parts and lower maintenance costs in comparison to gas-powered lifts.

- Batteries:Electric forklifts save hundreds of gallons of gasoline over the life of the battery. Also, their batteries can typically be recharged, which helps reduce landfill with toxic waste. With an electric forklift, you won’t have to worry about gas engine problems, too.

For more information about electric forklift batteries and safety standards, please see the OSHA Battery Charging and Changing Procedures.

Electric Forklifts: Good for the Environment

Battery life is one of the biggest advantages of electric forklift trucks over gas-powered forklifts — but it’s not the only advantage!

In addition to a long battery life, electric forklifts are versatile. They are also good for the environment, since they do not produce harmful emissions.

Furthermore, electric forklifts are quieter than gas lifts. The warning horns and backup signals can often be heard more clearly from an electric forklift in contrast to a gas-powered one.

Other benefits of electric forklifts include:

- No fuel tank reduces chances of fires

- Smaller size makes them easier to handle

- Better visibility (compared to trucks with liquid propane tanks mounted on the rear)

- Minimal maintenance

- Fewer breakdowns from fewer moving parts in the engine

- Longer service life

Review the benefits of electric forklifts closely. This can help you decide if an electric forklift can fulfill your business needs now and in the future.

How Do Electric Forklifts Work?

Unlike gas trucks, electric forks only have an accelerator and a brake pedal, and they do not have a clutch or inching pedals, which makes them easier to operate. An electric forklift driver does not have to rev the engine for fast lifting or to drive uphill. Many electrics even have automatic braking.

The absence of a clutch reduces driver fatigue with an electric forklift allows for smoother acceleration and braking as well. It’s one less part that will eventually wear out and have to be replaced, too.

With fewer electric forklift controls to handle, drivers can focus more on the load and task at hand than they can when they operate a gas-powered lift. Best of all, staying focused improves safety for the driver and nearby workers.

Electric Forklift Problems

Like any piece of equipment, electric forklifts have their downsides. The purchase price of electrics tends to be higher than that of a gas-powered lift. Most electrics have less power and lifting capacity that gas lifts, and their batteries can take up to eight hours to recharge, too.

Electrics are also easily damaged by weather such as rain or snow. Despite these electric forklift problems, most users will say the pros far outweigh the cons.

How to Charge an Electric Forklift

An electric forklift must be charged correctly to maximize the vehicle’s performance. To ensure an electric forklift is charged properly, read the owner’s manual. Here, you’ll find detailed instructions on how to charge the lift’s battery according to the manufacturer’s specifications.

Electric forklift batteries must be cleaned regularly, and special lifts may be required when a battery needs to be changed. Extra batteries must be stored onsite to prevent downtime.

Electric Forklifts and Safety Training

From a safety standpoint, OSHA views electric and gas forklifts as virtually identical. Even so, OSHA continues to update its forklift safety standards to account for electric forklifts.

Electric forklifts have certain battery changing standards and other power-related issues as well. Some of these should be part of your forklift maintenance plan. They are easy to follow, particularly if your drivers have the latest OSHA-compliant training from CertifyMe.net.

CertifyMe.net offers a great selection of forklift safety courses for both gas and electric trucks, and our classes meet and exceed the latest OSHA safety standards. To learn more about our forklift safety courses, please contact us online or call us today at 1-888-699-4800.